Fiber Bolstered Plastic-type (FRP) has revolutionized several sectors, providing a light-weight, long lasting, and flexible option to classic resources like metal and wooden. FRP manufacturers engage in an important role in bringing these innovative supplies to market, serving varied industries which range from aerospace and car to design and structure. Here’s an extensive help guide to everything you should find out about FRP manufacturers.

Material Expertise: what is frp focus on making composite resources using a mixture of high-power fibers for example fiberglass, carbon, or aramid, embedded in a resin matrix. This skills guarantees the production of FRP elements with exact mechanised attributes designed to meet the criteria of varied programs.

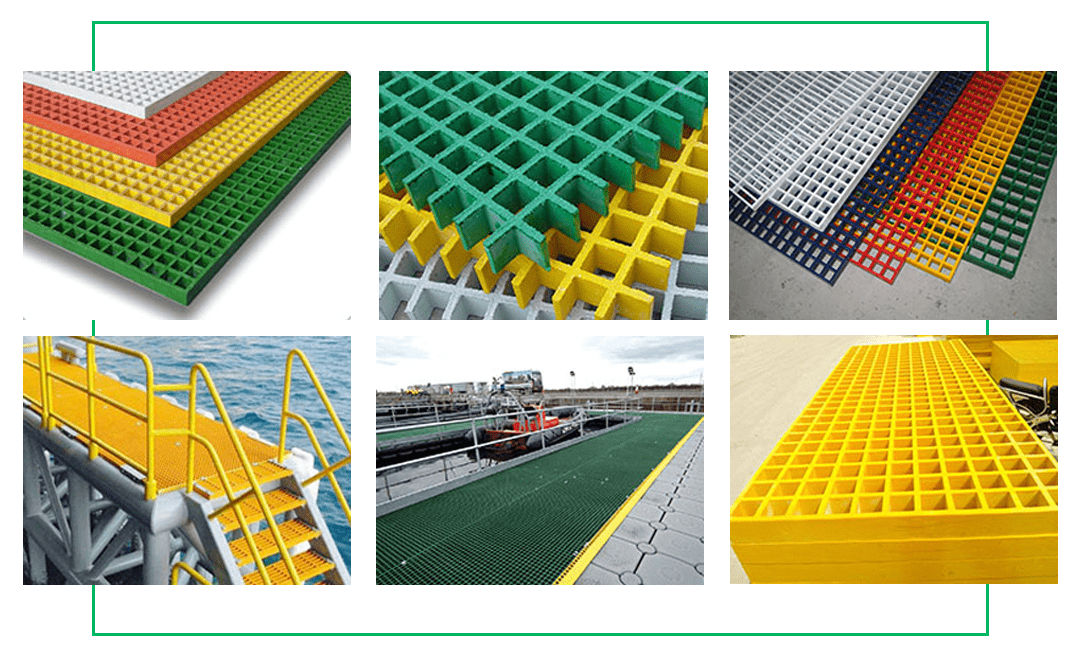

Changes: One of the crucial advantages of FRP manufacturers is in their ability to customize goods based on client requirements. Whether it’s the proportions, strength, shade, or surface area accomplish, manufacturers can modify FRP methods to match particular project requires, providing versatility unequaled by many other materials.

High quality Confidence: Established FRP manufacturers abide by rigorous top quality control procedures through the manufacturing process. From raw fabric variety to ultimate evaluation, every step is meticulously watched to ensure regularity and trustworthiness in the completed merchandise.

Creativity and R&D: Leading FRP manufacturers commit heavily in analysis and development to stay ahead of the curve. This commitment to advancement hard disks the growth of new supplies, developing tactics, and apps, forcing the boundaries of what can be done with FRP.

Ecological Sustainability: Several FRP manufacturers prioritize sustainability, utilizing eco-helpful resins and adding trying to recycle endeavours to their operations. By minimizing waste materials and decreasing environmental impact, these manufacturers play a role in a far more lasting future.

Software Assortment: FRP manufacturers serve a wide range of market sectors and programs. From lightweight elements for plane and autos to rust-resilient components for chemical processing vegetation and offshore programs, FRP realizes program in different areas because of its outstanding qualities.

Collaborative Partnerships: FRP manufacturers often team up with technicians, designers, and creative designers to develop revolutionary options for intricate obstacles. By cultivating relationships and utilizing combined knowledge, manufacturers ensure the effective incorporation of FRP materials into diverse projects.

To conclude, FRP manufacturers perform a vital role in traveling innovation and giving substantial-overall performance resources across various market sectors. Using their expertise, customization functionality, and persistence for high quality and sustainability, they still design the way forward for modern day engineering and development.